For a great visual of how it works click here: injection moulding animation

Injection moulding

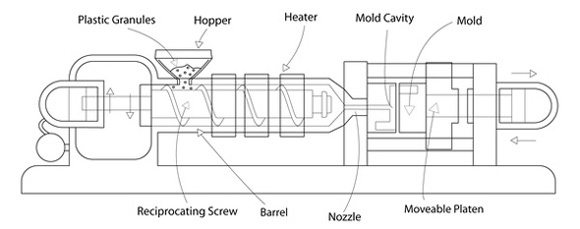

Injection moulding is the most commonly used and most cost-effective process of manufacturing plastic products. An injection moulding machine is used, this machine has a heated barrel that raw material is fed into via a hopper at the front of the injection moulding machine. By the force of a rotating screw the plastic material is heated to a liquid form and forced (injected) through the nozzle into a mould at the end of the injection moulding machine. Once the correct amount of material has been forced (injected) into the mould, the material then cools, and hardens to the shape of the mould. This newly formed plastic part is then ejected, and the injection moulding cycle begins again.

Injection moulding machine

Injection moulding for a multitude of plastics products

It is surprising if we evaluate the exact number of plastics products that are produced by injection moulding in a typical household or business. Milk cartons, jars, combs, toys, cooking utensils, household knickknacks, plant pots, are just to name a mere few products produced by injection moulding. The reason injection moulding is used for all these products is simply because it is the most cost-effective method of manufacturing plastic products.

Christchurch injection moulding at Plastech Industries

Here at Plastech Industries our Christchurch injection moulding process and injection moulding machinery provides the highest of quality when manufacturing plastics of any shape or size. If you require injection moulding manufacturing from one of our existing product lines, or you are seeking custom injection moulding manufacturing, then we invite you to call us for a no obligation quote

Christchurch injection moulding costs

Injection moulding is the most cost-effective way of manufacturing plastics. The initial set up of injection moulding does have a cost attached, however this is far outweighed by the significantly low price per unit especially when large injection moulding runs are performed. We are proud to say we are one of the most competitively priced New Zealand injection moulding companies, and offer a service second to none.

Injection moulding tooling and moulds matched to your requirements

When creating tooling for long-term use or large runs of injection moulding, high-grade materials are used such as high-grade pre-hardened steel or beryllium-copper. If however you require injection moulding services of short runs or prototypes, we can use more cost-effective materials for your tooling such as mild steel, aluminium, nickel or epoxy. We can work with you to establish the most appropriate material for your injection moulding tooling

Plastic manufacturing industry training

To learn more about Industry Training provided by PAMPITO please contact:

PAMPITO

Phone: 09 254 4877

E:mail: info@pampito.org.nz